Gemco Valve offers a full range of valves suitable for Industrial Machinery and Equipment applications

Gemco Valve provides valve solutions related to industrial machinery & equipment. This includes light density materials such as foods and pharmaceuticals; challenging bulk solids such as metal powder, dry food and bulk powder; plus, many other demanding applications in general chemical and solids processing industries. Gemco Valves can meet your sanitary, high temperature, and corrosive environment specifications.

Valves for industrial machinery & equipment are used to process a variety of applications and materials. Some of the most popular uses for Gemco Valves include the following materials.

Bulk Powder

Dry Food Powders

Metal Powder

Dry Food

Soy Pulp

Glycerin

Titanium Powder

General Chemical

Carbon Black

Sawdust

Pharma Powders

Lithium

Gemco Valves for Industrial Machinery & Equipment

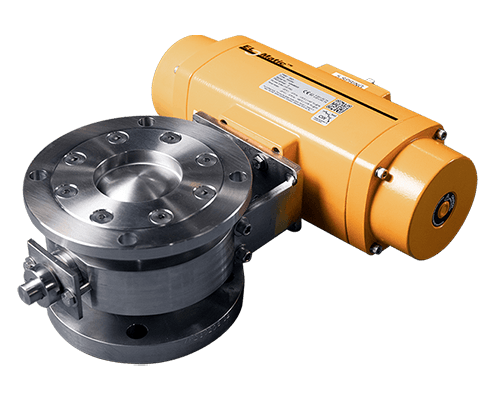

P21 High Performance Valve

The P21 is designed for ANSI class VI sealing from full vacuum to 150 PSI and is available in most alloys including carbon steel, stainless steel, Hastelloy and titanium. The P21 is offered with standard ANSI or DIN flanges and ISO actuator mounting. It can be configured with a solid reinforced Teflon (RPTFE) seat, metal seat or inflatable seat. Options include the full range of sanitary finishes and clean in place spray balls or nozzles.

Features and Benefits

- Designed for 10 bar and full vacuum

- Dust tight

- Hi temp 200°C to 800°C

- Can be configured with a solid reinforced Teflon (RPTFE), metal or inflatable seat.

- Can be engineered with flush mount pad to minimize or eliminate “dead space” cavities on mixer discharge.

- Options include the full range of sanitary finishes and clean in place spray balls or nozzles.

Materials of Construction

- Stainless Steel

- Hastelloy

- Carbon Steel

- Titanium

Specify the P21 Valve for your application and get a price quote.

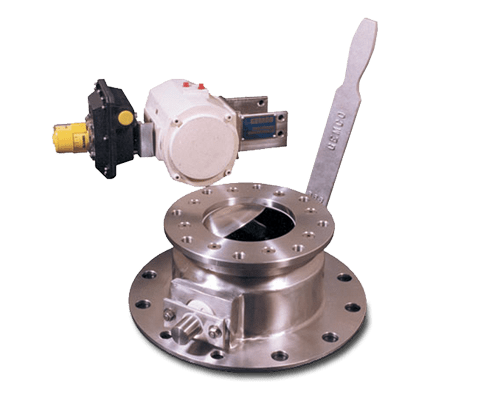

T Heavy Duty Valve

The Type T Valve is designed for heavy-duty service. It is typically used for slurries, abrasives, and heavy density materials. The T valve is available in cast stainless steel, cast iron as standard and can be fabricated from any weldable alloy with the full range of sanitary finishes. Options include high temperature or pressure (3 bar) designs, clean in place spray balls or nozzles and custom adapters or mountings.

Features and Benefits

- Designed for 3 bar and full vacuum

- Dust tight

- Hi temp 200°C to 800°C

- Can be configured with a solid reinforced Teflon (RPTFE), metal or inflatable seat.

- Can be engineered with flush mount pad to minimize or eliminate “dead space” cavities on mixer discharge.

- Options include the full range of sanitary finishes and clean in place spray balls or nozzles.

Materials of Construction

- Stainless Steel

- Hastelloy

- Carbon Steel

- Cast Iron

Specify the T Valve for your application and get a price quote.

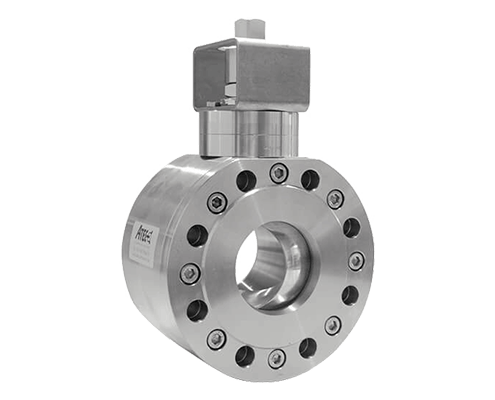

TLD Lightweight Valve

The TLD Valve is typically used for processing light density materials such as foods and pharmaceuticals and on rotating and mobile equipment where weight is a concern. It is available in a range of weldable alloys including 316L stainless steel and Hastelloy. The sanitary version of the TLD Valve has full interior and exterior polishes. ANSI and DIN drilling patterns are offered in addition to the Gemco standard pattern.

Features and Benefits

- Designed for 1 bar and full vacuum

- Dust tight

- Can be engineered with flush mount pad to minimize or eliminate “dead space” cavities on mixer discharge.

- Options include the full range of sanitary finishes and clean in place spray balls or nozzles.

Materials of Construction

- Stainless Steel

- Hastelloy

- Carbon Steel

Specify the TLD Valve for your application and get a price quote.

Sani K Valve

The Sani K Valve is designed to USDA/FDA and EHEDG guidelines eliminating threads, keyways and crevices. The split body design means the Sani K Valve can also be completely disassembled with simple hand tools, allowing quick and easy inspection and cleaning. It is used for charging/discharging or in-line with standard quick clamps allowing fast installation and removal.

Features and Benefits

- Dust tight

- Can be engineered with flush mount pad to minimize or eliminate “dead space” cavities on mixer discharge.

- Options include the full range of sanitary finishes and clean in place spray balls or nozzles.

Materials of Construction

- Stainless Steel

Specify the Sani K Valve for your application and get a price quote.

VB Ball Segment Valve

The VB Valve (1”/25 mm to 3”/75 mm) has full port for mass flow of most free flowing abrasive powders, slurries, liquids and gases. The VB design is a segmented ball that cycles through full flow. The VB is offered with standard flanged (ANSI/DIN), butt weld, tri clamp, or custom connections and is available in most machinable alloys.

Features and Benefits

- Designed for range of pressures and full vacuum.

- Low profile for minimal dead space on tank outlets.

- Abrasive resistance options.

- Hi temperatures options 200°C to 600°C

Materials of Construction

- Stainless Steel

- Carbon Steel

- Corrosive/high temperature resistance alloys

Specify the VB Valve for your application and get a price quote.

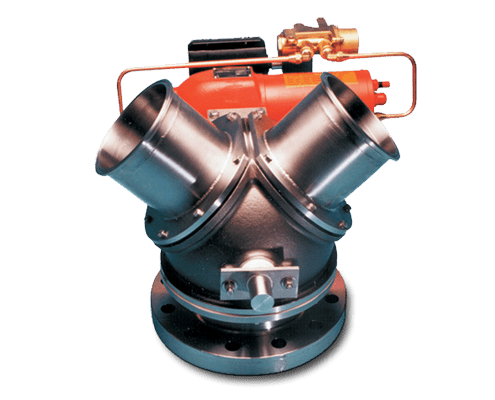

D-2 Diverter Valve 3-Way

The D-2 Diverter Valve places the Gemco Spherical Disc Valve in a ‘Y’ junction that allows the valve to select a product feed from one of the two inputs, or to direct one incoming stream of material to either of the two outlets. The standard D-2 valve is constructed of 316 stainless steel, but it can be made from any weldable alloy. The two ports can be positioned at 30 degrees, 45 degrees, or 60 degrees off the center-line of the third port.

The D2 Diverter Valve is designed to direct product from one input to either of two outputs or from either of two inputs to one outlet.

- Packing Station alternating valve

- Bypass valve

Specify the D-2 Valve for your application and get a price quote.

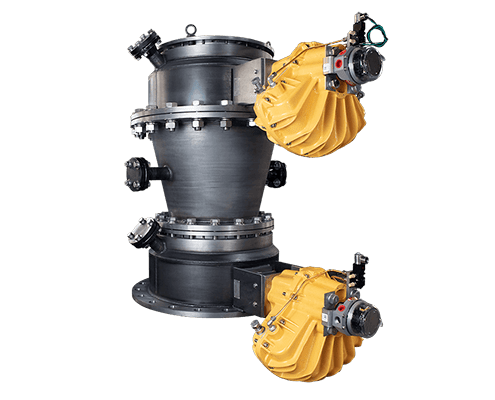

Double Dump (Airlock)

Gemco Valve Double Dump / Airlocks are designed to control the flow of material between two atmospheres. Consisting of two Gemco Valves connected by an intermediate chamber. Normal cycling varies from one to three times per minute. Slower cycling is possible and nominal material flows of one half to ten cubic feet per cycle are available. Chamber purge, sight glasses, clean-out ports, and automatic cycling controls are among the custom engineering options available.

Applications:

- Continuous Vacuum dryers

- Thin Film Evaporators (TFE)

- High Temperature Boilers

Specify the Double Dump for your application and get a price quote.