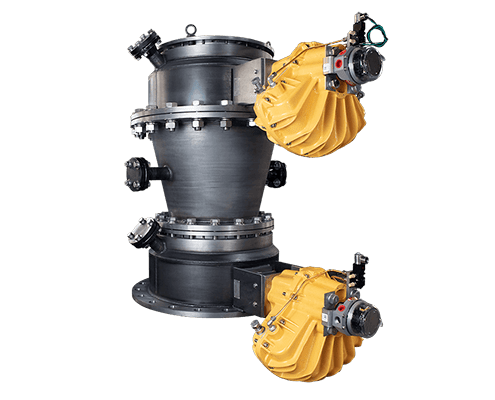

Gemco valves are available as Inlet Valve, Outlet Valve, and Pipe Inline Valve. There are a variety of options to fit your connection requirements. Mounting options include, but are not limited to ANSI 150#, ISO/DN PO10, Tri-Clamp, and Engineered Flush Mount. Flush valves allow for minimizing or eliminating “dead space”. The Sani K Valve can be completely disassembled with simple hand tools, allowing quick and easy inspection and cleaning.

Gemco Valves are used for charging/discharging or inline and have some unique advantages for handling difficult dry and slurry material applications.

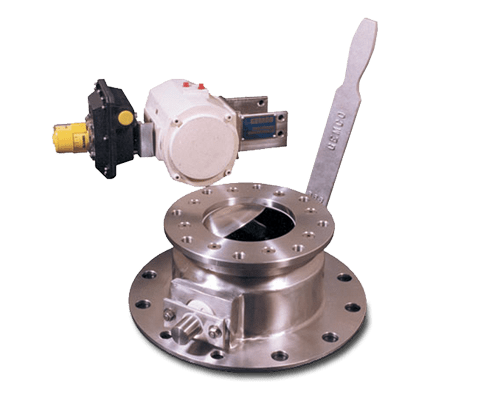

Inlet Valve

Material falls unobstructed through the inlet opening. The Gemco valve provides clearance that prevents powder jamming between the disc and housing.

Blender Inlet Valve

Container Inlet Valve

Hopper Inlet Valve

Mixer Inlet Valve

Processor Inlet Valve

Reactor Inlet Valve

Sifter Inlet Valve

Screener Inlet Valve

Tank Inlet Valve

Vessel Inlet Valve

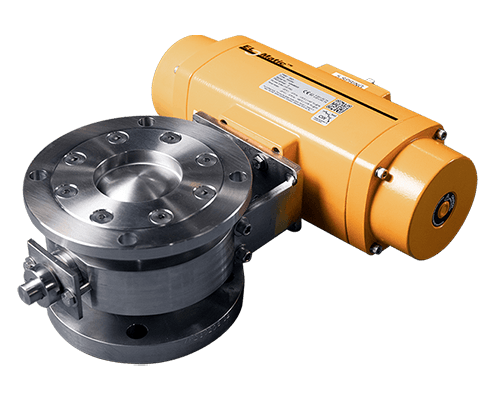

Outlet Valve

The Gemco Valve shutoff disc swings completely out of the flow of the material preventing bridging and promoting mass flow. The valve body discharge may be configured with a flush mount.

Blender Outlet Valve

Container Outlet Valve

Hopper Outlet Valve

Mixer Outlet Valve

Processor Outlet Valve

Reactor Outlet Valve

Sifter Outlet Valve

Screener Outlet Valve

Tank Outlet Valve

Vessel Outlet Valve

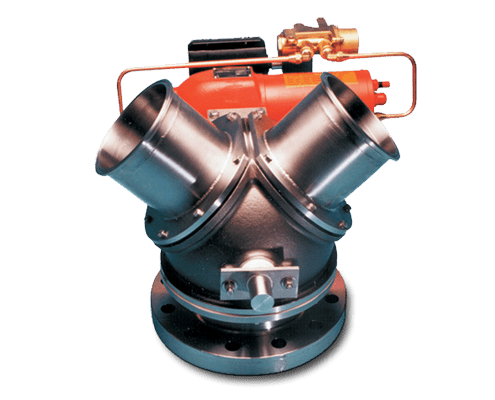

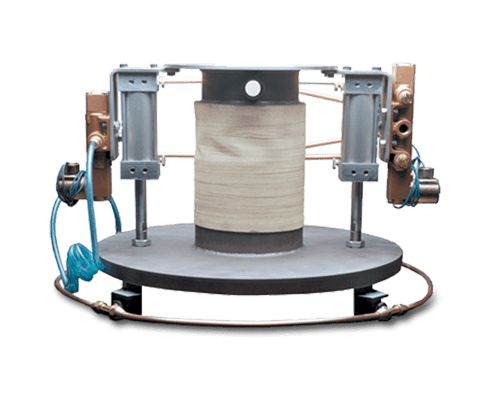

Pipe Inline Valve

Gemco Valves provide tight shut-off, predictable control, and ease of operation. There are quite a few different types of connections used to install valves in the piping of process systems. Flanges are the second most used method after welding. Using flanges adds flexibility when maintaining piping systems by allowing for easier disassembly and improved access to system components.