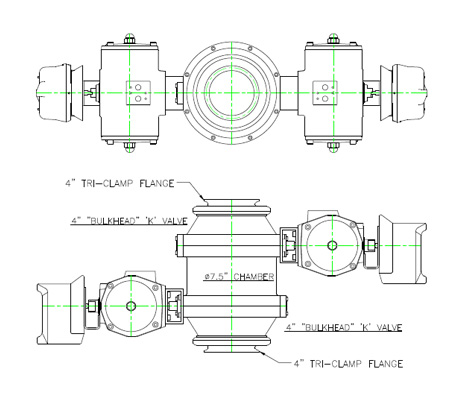

Gemco Airlocks are designed to control the flow of material between two atmospheres. Consisting of two Gemco Valves connected by an intermediate chamber and are often used instead of rotary feeders, which are prone to high maintenance and leakage of material and gases. Normal cycling varies from one to three times per minute. Slower cycling is possible and nominal material flows of one half to ten cubic feet per cycle are available. Chamber purge, sight glasses, clean-out ports, and automatic cycling controls are among the custom engineering options available.

Commonly called double dump valves Gemco Airlocks are configured from two standard Gemco Valves with a chamber to control the flow of material between two atmospheres.

Applications:

- Continuous Vacuum dryers

- Thin Film Evaporators (TFE)

- High Temperature Boilers