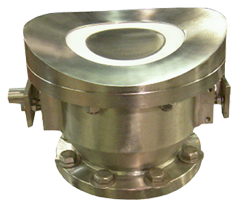

Continuing its long held commitment to the design, development and manufacture of innovative, durable, solution-oriented products, Gemco Valve introduces the flush mount valve. In addition to Gemco Valve’s standard features of full port opening to prevent bridging, a self-cleaning seal area to promote longer life and no pinch points which eliminates jamming the new option is designed to eliminate the dead space around the valve outlet. Dead space can result in unmixed product hardening causing material bridging during discharge.

Continuing its long held commitment to the design, development and manufacture of innovative, durable, solution-oriented products, Gemco Valve introduces the flush mount valve. In addition to Gemco Valve’s standard features of full port opening to prevent bridging, a self-cleaning seal area to promote longer life and no pinch points which eliminates jamming the new option is designed to eliminate the dead space around the valve outlet. Dead space can result in unmixed product hardening causing material bridging during discharge.

“Hardnening and bridging issues often cause downtime, slowing production and possibly even resulting in valve damage and/or excessive wear,” said Gemco Valve President, Jim Lenihan. “The new proprietary flush mount design is a direct result of listening and responding to customer needs.” Using state of the art 3D engineering and leading edge CAD/CAM production methods, Gemco Valve engineers and machinists have configured a flush mount that can match ribbon mixer diameters and even compound cone mixer profiles, thus eliminating dead space.

Flush mounting is available as customized, engineered option for most Gemco Valves.