Solutia, formerly Monsanto Company needed an 8″dia. valve to unload a dried phosphate salt from a mixer-dryer. Conventional discharge ports and valves were useless. The firm solved the problem with a GemcoValve specifically designed to break through caked material as the disc opens.

The process requires that slurry be mixed then dried, in a single vessel. The next step is to discharge the dry solids through a valve at the bottom of the vessel. As the slurry dries, it forms a cake that can plug the bottom discharge port.

This caking precludes the use of a conventional valve welded to a nozzle at the bottom of the vessel, since any space between the valve disc and the vessel would plug with cake. Even a flush-mounted valve would not be successful since cake forming over the top of the valve would remain intact even after the valve opened, restricting or totally blocking flow.

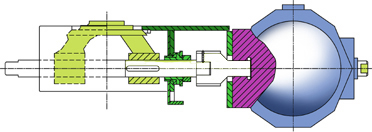

The valve Solutia needed had to meet four criteria: (1) there could be no dead space between the valve and the vessel; (2) the valve had to break the cake on the bottom of the vessel as the valve opened; (3) it had to be liquid-tight; and (4) the valve needed an 8-in. port. No standard valves were available that met all four requirements. Solutia called on GemcoValve to design a special valve for the application. Using the Gemco spherical-disc seal technology that Solutia had found successful in other solids applications, Gemco and Solutia engineers designed a valve that produced the required torque and plowing action to break through the cake. The customized valve also seals liquid-tight, and the disc fits directly against the bottom of the vessel to eliminate dead space. Key to the valve’s success is a stepped disc that offers the required plowing action. The use of a segmented ball disc provides the full-port opening for rapid, unobstructed flow through the valve.

Other features essential to the valve’s success include:

- An oversized actuator to produce the high torque required to break through the cake

- A valve shaft constructed of Ferralium 255-31SF that can handle the 20,000-in.-lb. torque required. This alloy has three times the stress rating of conventional Type 316 stainless steel

- Shaft eccentric bushings constructed of Ultem 1000 (Polyetherimide, made by GE Plastics). Unlike PTFE (Polytetrafluoroethylene), Ultem 1000 can support the high shaft radial load without permanent deformation. In addition to providing the required mechanical stability, this bushing material meets food-grade requirements

- A valve seat of Stellite # 21 provides tight sealing with the Stellite # 6 rim of the type 316 stainless steel disc while offering the high wear-resistance required.

Operating at temperatures as hot as 400°F, this customized valve has been in operation since 1989. The valve has required little maintenance, and Solutia plans to use other valves of this design in similar applications. As an outgrowth of this project, GemcoValve now offers the stepped-disc design in its product lines.