Extreme Temperature Powder Valve

Gemco Valve and ATEC Valve combined their expertise and technologies to produce a unique solution for processing extreme temperature abrasive powders for GTI – Gas Technology Institute is a cutting- edge energy business, located in Des Plaines Illinois. GTI solves important energy challenges, turning raw technology into practical solutions.

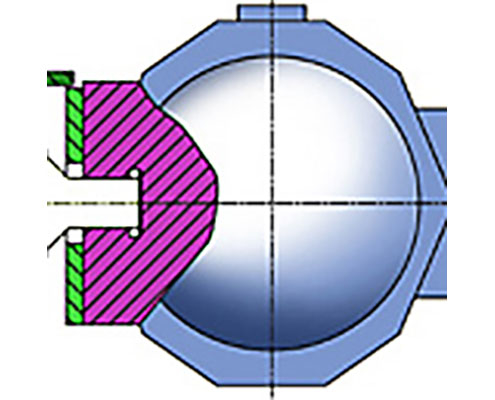

Spherical disc valve solution

Gemco Valve’s full port and self-wiping action spherical disc valve delivered without delay meets food manufacturer’s custom requirements.

An industry-leading importer and custom manufacturer offering an extensive line of spices, seasonings, and specialty food ingredients needed a valve for a new installation at their US West processing facility.

Case Study Pharmaceutical

One of the world’s largest research-based pharmaceutical companies discovers, develops, manufactures, and markets leading prescription medicines for humans and animals and many globally recognized consumer brands. In the United States, at one of their five primary research sites, they also manufacture and package a family of non-prescription dietary and nutrition products for both the American and international markets.

Gemco Valve tested for Moon Duty

A specially designed spherical disc valve manufactured by Gemco Valve Company is being tested as part of a system that will extract oxygen from volcanic ash rich in minerals. The recovered oxygen will be used by the lunar space station that NASA plans to construct as part of extended habitation on the moon.

Nestlé USA and USDA/FDA compliant K-Valve Airlock

Nestlé USA, part of Nestlé S.A., a world leader in infant nutrition, manufactures Nestlé Good Start Supreme DHA & ARA. The new formula contains two fatty acids, docosahexaenoic acid and arachidonic acid, also known as DHA and ARA, which are naturally found in breast milk and have been linked with improved brain and visual development in babies.

Double actuators solves valve-jamming problem

Valve replaces a plug valve in a metal starch application. Jim Shirley was in a bit of a bind in more ways than one. As General Manager of Aqua Sol, a manufacturer of metal starches for the textiles dyes industry in Pineville, NC, Mr. Shirley was having difficulties in production with his Plug Valves.

Continuous vacuum dryer system eliminates batch variability

Problem: Schenectady Company needed a continuous vacuum dryer to match the continuous manufacturing process for making a resinous product. Drying had been carried out in batch dryers at the plant and through “contract” drying facilities, but increased production was needed to handle the demand for the products. A careful evaluation of equipment was essential to assure that any continuous dryer selected could be fed and discharged without clogging or jamming up, a common problem encountered when a continuous dryer is operating under a pressurized or vacuum environment.

Stepped-Disc overcomes caking problem

Solutia, formerly Monsanto Company needed an 8″dia. valve to unload a dried phosphate salt from a mixer-dryer. Conventional discharge ports and valves were useless. The firm solved the problem with a Gemco Valve specifically designed to break through caked material as the disc opens.