Due to the unique nature of these mixtures a valve for slurries require careful consideration of all options and related customizations. Gemco Valve’s highly customizable product line has unique advantages that overcome the typical problems associated with handling slurry materials.

Hover over the cards below to see the most common problems that arise when processing slurry materials using traditional ball, butterfly and slide gate valves and the solution that Gemco Valve can can provide.

Interested to learn more? Complete the Request Quote form to the best of your ability and a representative will contact you for further details.

Common Slurries Our Valves Can Process

Abrasive

Abrasive High Temperature

Wet Filter Cake/Pharmaceutical

Acetone

Alum Wet Catalyst

Carbon Black Solids

Chlorine

Cocoa

Confidential Bulk Powder

Dense Phase Convey Hi Temperature Alumina Powder

Food Spices

Glycerin

Hot Dirty Glycerin Fatty Salts

Hot Glue

Liquid Slurry Form

Magnesium Oxide Powder

Methanol

Organic Liquids

Pharma Powders

Pharmaceutical Wet Cake

Salt Slurry N2

Silica Sand

Sodium Chloride Salt

Silicone Various Colors

Wet Cake

Based on our experience with these materials, we can recommend the best valve options for your application.

Valve Options & Customization

What material options are there?

The slurry to be processed will dictate the product contact material. Cast iron, carbon steels, and aluminum can be used for many industrial applications. Corrosive processes will call for the use of stainless steel, and in some cases material laden with solvents or other corrosives will justify the extra expense of using Hastelloy‚ or other high nickel alloy to prolong valve life.

For stainless steel valves of welded construction, 316L grade is preferred. It is more corrosion resistant than 316 stainless steel, and the lower carbon content prevents carbon precipitating from the welded joints.

What seat materials are available?

Very abrasive material will tend to dictate using metal seats versus the more commonly used reinforced Teflon seats.

The metal seal will give longer life and can be used at higher temperatures than Teflon but the shut-off sealing is limited to dust tight, ANSI class IV or ANSI class V. Reinforced Teflon can be used up to 450 degrees F (230 C), and provide Class VI shut-off.

What is the cleanability?

The sanitary requirements of the process will govern the surface finishes and other sanitary options. We define our finishes as follows:

No surface finish (Ra) specified. Sometimes referred to as “mill finish” or “as cast”. Fabricated valves will only have the internal welds ground smooth and flush. Common in general industrial applications where cross contamination or cleanability are not a concern.

#2 finish – Ra 33 to 65 microinch – 150 to 180 grit. Also referred to as “buffed, blended or uniform appearance finish”. Often specified for the outside of equipment that will be washed down.

#4 polish – Ra 16 to 32 microinch – 180 to 240 grit. All fabrication and handling marks removed. Surface is buffed to a uniform satin finish. The #4 polish is typical for the interior of equipment that needs to be cleaned between batches to prevent cross contamination.

#7 polish – Ra 10 to 15 microinch – 240 to 320 grit. All surface imperfections are repaired. Often referred to as “pit free” and “mirror finish”. Used for high purity applications such as processing potent pharmaceutical actives. Also used for products that tend to adhere to surfaces.

For automatic cleaning, spray balls or jets should be considered. Another option is a valve that can be dismantled by hand for inspection and cleaning. For safety reasons the size of such valves are typically limited to an 8″ port diameter due to the weight of individual components.

How much does the valve weigh?

The weight of a valve is especially important for mobile or rotating equipment. High performance and heavy-duty models can weigh four times as much as its regular-duty counterpart. Dust tight, full vacuum, and 1 bar service, is considered to be regular duty service. 90 PSI (6bar) to 150 PSI (10bar) is high performance. An 8-inch manually operated regular duty valve can weigh 55 lbs (25Kg), versus nearly 200 lbs. (90Kg) for an 8″ high performance model.

What are the mounting arrangements?

The typical ANSI 150 # and DIN drilling is used as an industry standard for heavy duty and high performance models. Quick clamps can also be used for applications up to 30PSI (2bar) and port sizes up to 8″.

Some valves will include blind tapped holes, which may be a problem if the valve is mating with existing blind tapped holes. Another option is to choose oversized flanges, which allows for through holes. For regular duty service valves, ANSI and DIN bolting can be overkill and alternative bolting patterns are available.

How is actuation handled?

As with other quarter turn valves; levers, gear drives or chain operators are available. Pneumatic and hydraulic, operators are available in double acting or fail-safe modes. Pneumatic operation should be the first choice for price, reliability, and speed. When handling solids a higher factor of safety is used to calculate seat torque requirements. The factor is typically 1.5 instead of the 1.25 used for liquid and gas valve calculations.

For solids that “set-up” or harden oversized actuator and specially designed discs that can break through the hardened cake are used. Actuators are typically sized for 80-PSI (5.3 bar) pressure. If the available supply air pressure is dependably higher (100 to 120PSI) or lower (40 to 60 PSI), this will factor in the sizing of the actuator.

For fail-safe operation, spring return actuators are the norm. When a spring return type actuator is used, it is oversized to compensate for the spring as well as the unseating, run, and seating torque required for valve operation. This can lead to weight and space problems as well as extra cost. An alternate fail-safe option is to use a double acting actuator with a pneumatic accumulator sufficiently sized to close the valve. If there is a loss of pneumatic pressure, a pressure switch activates the accumulator and operates the valve.

What kind of flow control is possible?

Fast acting (1 to 5 seconds), quarter turn valves are ideal for flow control of solids. A pneumatic (3 to 15 PSI) or electro-pneumatic (4 to 20 milliampere) positioner can take a signal from a manual adjusted pressure regulator, or from a computer controller. The pneumatic positioner is often used in manually operated filling stations, while the electro-pneumatic positioner is typical for automatic loss-in-weight systems.

Gemco Valves For Slurries

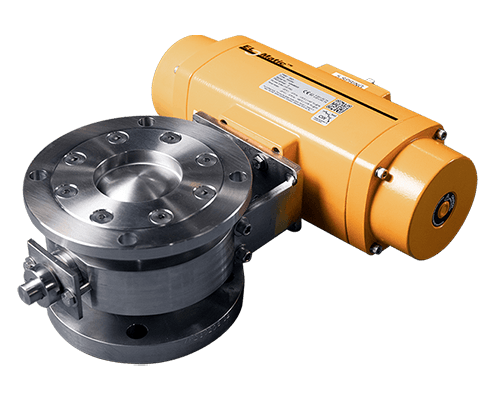

P21 High Performance Valve

The P21 is designed for ANSI class VI sealing from full vacuum to 150 PSI and is available in most alloys including carbon steel, stainless steel, Hastelloy and titanium. The P21 is offered with standard ANSI or DIN flanges and ISO actuator mounting. It can be configured with a solid reinforced Teflon (RPTFE) seat, metal seat or inflatable seat. Options include the full range of sanitary finishes and clean in place spray balls or nozzles.

Features and Benefits

- Designed for 10 bar and full vacuum

- Dust tight

- Hi temp 200°C to 800°C

- Can be configured with a solid reinforced Teflon (RPTFE), metal or inflatable seat.

- Can be engineered with flush mount pad to minimize or eliminate “dead space” cavities on mixer discharge.

- Options include the full range of sanitary finishes and clean in place spray balls or nozzles.

Materials of Construction

- Stainless Steel

- Hastelloy

- Carbon Steel

- Titanium

Specify the P21 Valve for your application and get a price quote.

T Heavy Duty Valve

The Type T Valve is designed for heavy-duty service. It is typically used for slurries, abrasives, and heavy density materials. The T valve is available in cast stainless steel, cast iron as standard and can be fabricated from any weldable alloy with the full range of sanitary finishes. Options include high temperature or pressure (3 bar) designs, clean in place spray balls or nozzles and custom adapters or mountings.

Features and Benefits

- Designed for 3 bar and full vacuum

- Dust tight

- Hi temp 200°C to 800°C

- Can be configured with a solid reinforced Teflon (RPTFE), metal or inflatable seat.

- Can be engineered with flush mount pad to minimize or eliminate “dead space” cavities on mixer discharge.

- Options include the full range of sanitary finishes and clean in place spray balls or nozzles.

Materials of Construction

- Stainless Steel

- Hastelloy

- Carbon Steel

- Cast Iron

Specify the T Valve for your application and get a price quote.

TLD Lightweight Valve

The TLD Valve is typically used for processing light density materials such as foods and pharmaceuticals and on rotating and mobile equipment where weight is a concern. It is available in a range of weldable alloys including 316L stainless steel and Hastelloy. The sanitary version of the TLD Valve has full interior and exterior polishes. ANSI and DIN drilling patterns are offered in addition to the Gemco standard pattern.

Features and Benefits

- Designed for 1 bar and full vacuum

- Dust tight

- Can be engineered with flush mount pad to minimize or eliminate “dead space” cavities on mixer discharge.

- Options include the full range of sanitary finishes and clean in place spray balls or nozzles.

Materials of Construction

- Stainless Steel

- Hastelloy

- Carbon Steel

Specify the TLD Valve for your application and get a price quote.

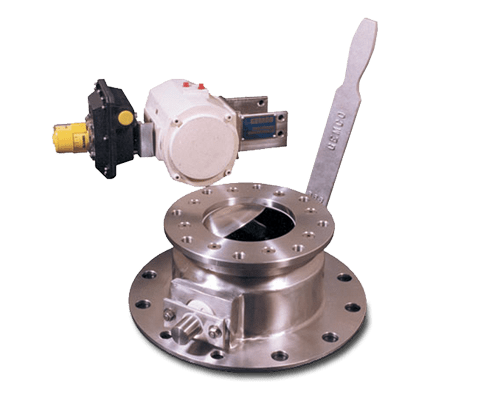

Sani K Valve

The Sani K Valve is designed to USDA/FDA and EHEDG guidelines eliminating threads, keyways and crevices. The split body design means the Sani K Valve can also be completely disassembled with simple hand tools, allowing quick and easy inspection and cleaning. It is used for charging/discharging or in-line with standard quick clamps allowing fast installation and removal.

Features and Benefits

- Dust tight

- Can be engineered with flush mount pad to minimize or eliminate “dead space” cavities on mixer discharge.

- Options include the full range of sanitary finishes and clean in place spray balls or nozzles.

Materials of Construction

- Stainless Steel

Specify the Sani K Valve for your application and get a price quote.

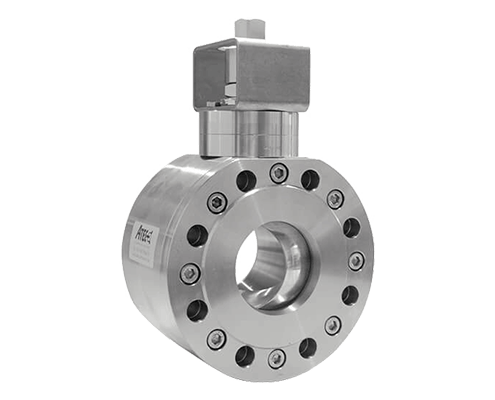

VB Ball Segment Valve

The VB Valve (1”/25 mm to 3”/75 mm) has full port for mass flow of most free flowing abrasive powders, slurries, liquids and gases. The VB design is a segmented ball that cycles through full flow. The VB is offered with standard flanged (ANSI/DIN), butt weld, tri clamp, or custom connections and is available in most machinable alloys.

Features and Benefits

- Designed for range of pressures and full vacuum.

- Low profile for minimal dead space on tank outlets.

- Abrasive resistance options.

- Hi temperatures options 200°C to 600°C

Materials of Construction

- Stainless Steel

- Carbon Steel

- Corrosive/high temperature resistance alloys

Specify the VB Valve for your application and get a price quote.

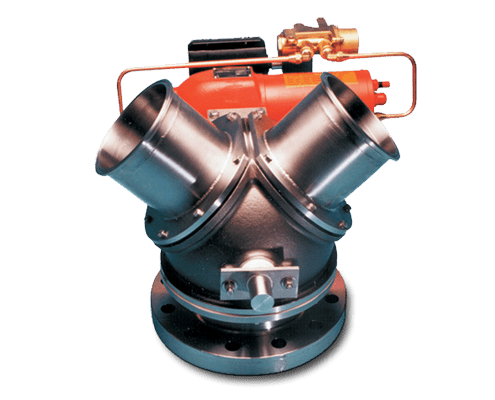

D-2 Diverter Valve 3-Way

The D-2 Diverter Valve places the Gemco Spherical Disc Valve in a ‘Y’ junction that allows the valve to select a product feed from one of the two inputs, or to direct one incoming stream of material to either of the two outlets. The standard D-2 valve is constructed of 316 stainless steel, but it can be made from any weldable alloy. The two ports can be positioned at 30 degrees, 45 degrees, or 60 degrees off the center-line of the third port.

The D2 Diverter Valve is designed to direct product from one input to either of two outputs or from either of two inputs to one outlet.

- Packing Station alternating valve

- Bypass valve

Specify the D-2 Valve for your application and get a price quote.

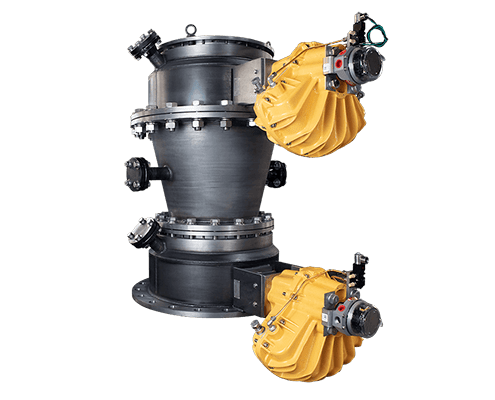

Double Dump (Airlock)

Gemco Valve Double Dump / Airlocks are designed to control the flow of material between two atmospheres. Consisting of two Gemco Valves connected by an intermediate chamber. Normal cycling varies from one to three times per minute. Slower cycling is possible and nominal material flows of one half to ten cubic feet per cycle are available. Chamber purge, sight glasses, clean-out ports, and automatic cycling controls are among the custom engineering options available.

Applications:

- Continuous Vacuum dryers

- Thin Film Evaporators (TFE)

- High Temperature Boilers

Specify the Double Dump for your application and get a price quote.