https://gemcovalve.com/wp-content/uploads/2022/08/portfolio-p21-high-performance-valve.png

400

495

Pieter

https://gemcovalve.com/wp-content/uploads/2021/12/gemcovalve_logo-white.svg

Pieter2014-03-09 16:06:232025-04-04 15:13:31P21 High Performance Valve

https://gemcovalve.com/wp-content/uploads/2022/08/portfolio-p21-high-performance-valve.png

400

495

Pieter

https://gemcovalve.com/wp-content/uploads/2021/12/gemcovalve_logo-white.svg

Pieter2014-03-09 16:06:232025-04-04 15:13:31P21 High Performance ValveEngineered Valve Solutions

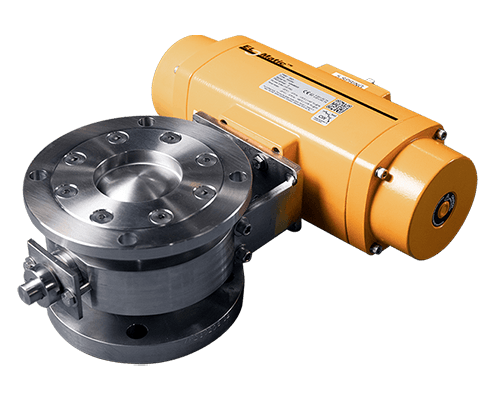

Powders, Dry Bulk Materials, And Slurries

Powders, dry bulk materials, and slurries come in a wide range of sizes, textures, and consistencies. Gemco Valve provides solutions for the full range of materials, applications, and processes. Including light density materials such as foods and pharmaceuticals; Challenging bulk solids such as sand, gravel, metal powder, and ceramics; Plus, many other demanding applications in general chemical and solids processing industries. Gemco Valves can meet your sanitary, high temperature, and corrosive environment specifications.

The Gemco Valve Advantage

Learn About The Three Major Advantages Of The Gemco Valve Design

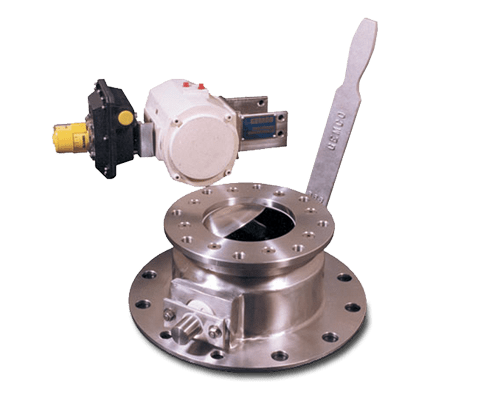

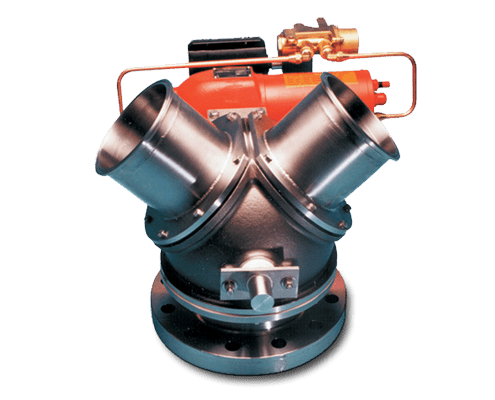

Full Port Openings

Gemco Valve’s solution for material bridging: Unlike a butterfly valve the shutoff disc swings completely out of the flow of the material preventing bridging and promoting mass flow.

Self-Cleaning Areas

Gemco Valve’s solution for material jamming: Unlike a gatevalve, the self-cleaning action tends to wipe the material away from the sealing area instead of jamming abrasives into the sealing track.

No Pinch Points

Gemco Valve’s solution for material packing: With a spherical disc or dome valve shape there are no tight cavities for materials to pack and jam-up causing the seat to tear or the operation to cease.

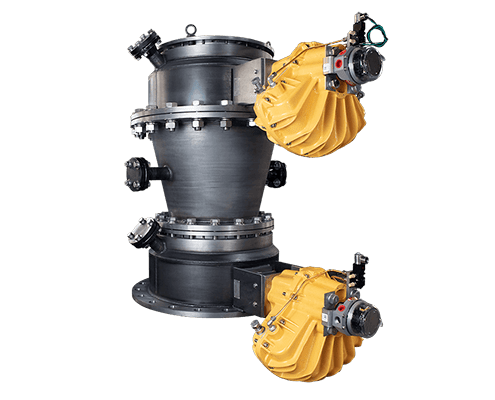

Featured Valve

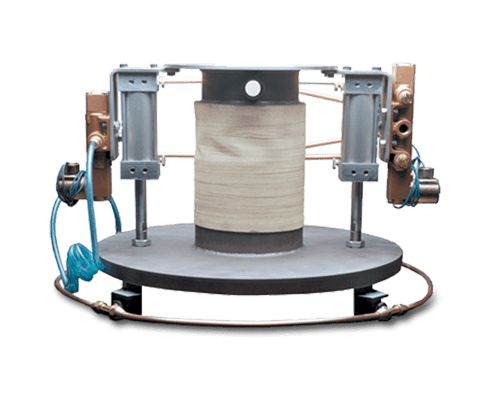

Sani K Next Generation Spherical Disc

The Sani K Valve is designed to USDA/FDA and EHEDG guidelines eliminating threads, keyways and crevices. The split body design means the Sani K Valve can also be completely disassembled with simple hand tools, allowing quick and easy inspection and cleaning. It is used for charging/discharging or in-line with standard quick clamps allowing fast installation and removal.

Applications for the Sani K Valve include uses in food, pharmaceutical and nutraceutical industries or anywhere where cleanability and quick change over is required. Many of our customers use the Sani K Valve for dry food powders, spices, plastic pellets, and metal powders among other media.